At BAG Electronics, manufacturing is more than just a process—it’s a disciplined, technology-driven practice built around quality, traceability, and responsiveness. We specialize in complex PCB assembly and full-system integration for high-reliability industries including automotive, industrial, lighting, and medical electronics.

Our manufacturing operations are optimized for flexibility and scalability, whether supporting early-stage product launches or full-scale global production. With a commitment to lean principles, process automation, and quality excellence, we help our partners reduce time-to-market, lower cost, and improve product consistency across the lifecycle.

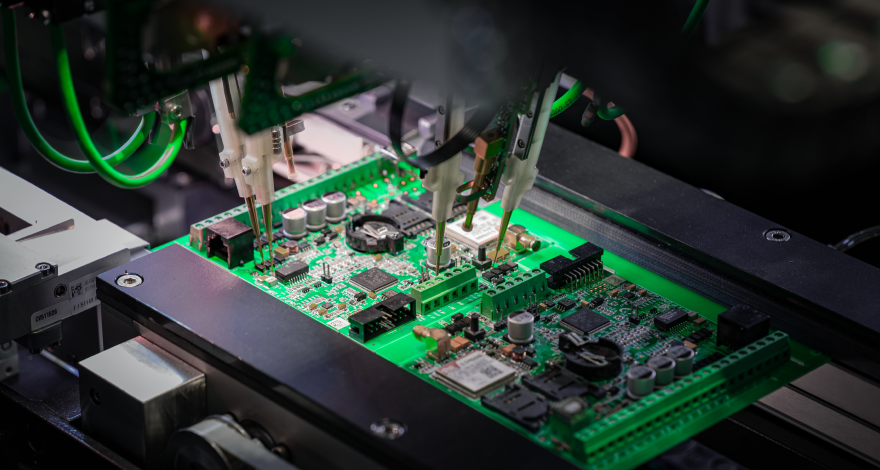

High-speed, precision placement lines with inline AOI, SPI, and reflow profiling. Supports high-mix/low-volume and high-volume/low-mix scenarios with automotive-grade traceability.

Complete electromechanical integration, including wire harnessing, thermal interface installation, functional testing, and final packaging.

ESD-controlled, clean environments for sensitive applications in medical.

Protective solutions for harsh environments using automated and manual application techniques.

ICT, functional testing, boundary scan, burn-in, and in-circuit programming ensure end-to-end product quality and compliance.

Whether you’re building next-gen EV controllers or mission-critical electronics, BAG Electronics delivers manufacturing excellence backed by engineering depth, operational discipline, and strategic foresight.